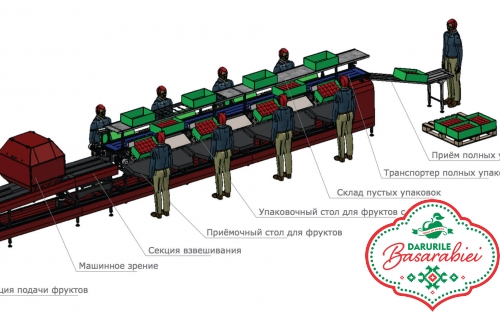

Sorting machine RDS

HE CLASSIFICATION PARAMETERS:

- Size

The classification of apple according to the size, proceeds through the analysis of a series of images including characteristics of apple (e.g its shape)

- Weight

Using the electronic strain gauges, digital signal filtration and the reduction of noises,fast and cutting edge weight module enables precise calculations on sorted apples in real time thus significantly shortening the measurement time.

- Colour

The cameras installed in Visort system analyze a series of images and enable recognition of the product according to the colour.

- Internal and external quality

Using the cameras Visort system inspects product surface and recognizes external damages (e.g. apple scab, defects due to mechanical cause) as well as internal (demages under the peel).

Advantages:

- Sorter’s algorithms are based on Linux and allow to analyse products in real time. Due to this innovative solution specific parameters of the products are calculated. Algorithms designed by Sorter distinguish ViSort from similar visual systems, which are based on a comparison of products’ images with the standard pattern.

- ViSort can be adapted to any sorting machine, which enhances sorting processes.

- System configuration can be customized to customers’ needs.

- We guarantee constant quality due to certified durable stainless steel components and consistent performance.

- User-friendly interface which enables easy change of the parameters in real time.

EXTRA OPTIONS OF ViSort:

| EXIT CONTROL |

|

| SETTINGS TEMPLATES RECORD |

ViSort allows you to record settings, sorting ways and speed.

|

| SESSION REGISTRATION |

During the sorting process, ViSort allows you to record and store the sorting results including suppliers and clients. The session results are available and printable at any time. |

| COOPERATION WITH LABELLING MACHINES | ViSort cooperates with the labelling machines and enables products labelling during the portioning process. |

| MACHINES SPEED CONTROL | ViSort allows you to control machine speed and delivery. |

| COOPERATION WITH AUTOMATION | ViSort allows you to cooperate with PLC controllers, inverters and safety circuit. |

| LED STROBED LIGHTING | Led strobed lighting reduces the energy consumption and does not heat the product during the analysis process. |